Client Background

Novanta is a trusted technology partner to medical & advanced industrial OEMs, with proprietary expertise in photonics, vision, & precision motion technologies. Their mission-critical components deliver extreme precision & performance, enabling customers to improve productivity & performance.

"Triniti’s Arena PLM Adapter connects to 6 different workspaces of Arena PLM thereby helping Novanta business units manage and synchronize product master data in the PLM system and our Oracle EBS transactional system. Throughout product lifecycle--from Product Design, Production through to end-of-life stage, product transactional attributes are well controlled through the adapter into Oracle EBS. Triniti has always worked as a Partner with Novanta. They have supported 6 Arena workspace implementations for different Business Units, different data, different processes, and different challenges. Triniti has always assisted in making our projects successful, as well as supporting day-to-day success. It is their knowledge and dedication to Novanta’s success that stands out. Thank you Triniti for helping Novanta streamline master data between PLM and ERP systems"

- Wendy Baker, Senior Arena Systems Analyst, Novanta Inc.

Outcomes

- Increased collaboration among engineering, procurement, shop floor, planning, and sales

- A single version of truth for Items and Bills of Material (BOM)

- Cradle to grave integration from new product introduction (NPI) and the entire lifecycle

- Ensures FDA mandated 'Service life' requirement for discontinued items

- Provided greater downstream visibility and data consistency by enabling Arena PLM to communicate with Oracle EBS seamlessly

- Attribute management through user-defined business rules for each stage in the life cycle

- Streamlined master data maintenance in manufacturing and sales organizations

- Kept product data on TRAC (Timely, Reliable, Accurate and Complete)

- Highlighted data inconsistencies through error reporting

Opportunities/ Challenges

- Operational errors resulting from data maintenance in PLM and ERP

- Latency in data synchronization between PLM and ERP systems

- Custom business rules for each business unit and product verticals

- Integrate multiple Arena workspaces

- To eliminate manual update of Items/BOMs in Oracle ERP and control all product data maintenance

- Standardize master data maintenance using ECOs and MCOs

Solution Highlights

- Six different PLM Workspaces integrated with Oracle EBS. Each business division has a separate PLM workspace

- Based on the workspace, integration handles seven manufacturing and four sales organizations

- Data volume handled by the integration per year:

- 40,000 ECs

- 80,000 Items

- 20,000 BOMs

- Compliance information such as Country of Origin, ECCN, HTS Code

- Efficient error management by notifying users of errored records through alerts and emails

- Exceptions Management by users and not by IT

Supported Business Objects

- Products

- Product Revisions

- Product Categories

- BOMs

- BOM Designators

- Approved Manufacturers and Suppliers

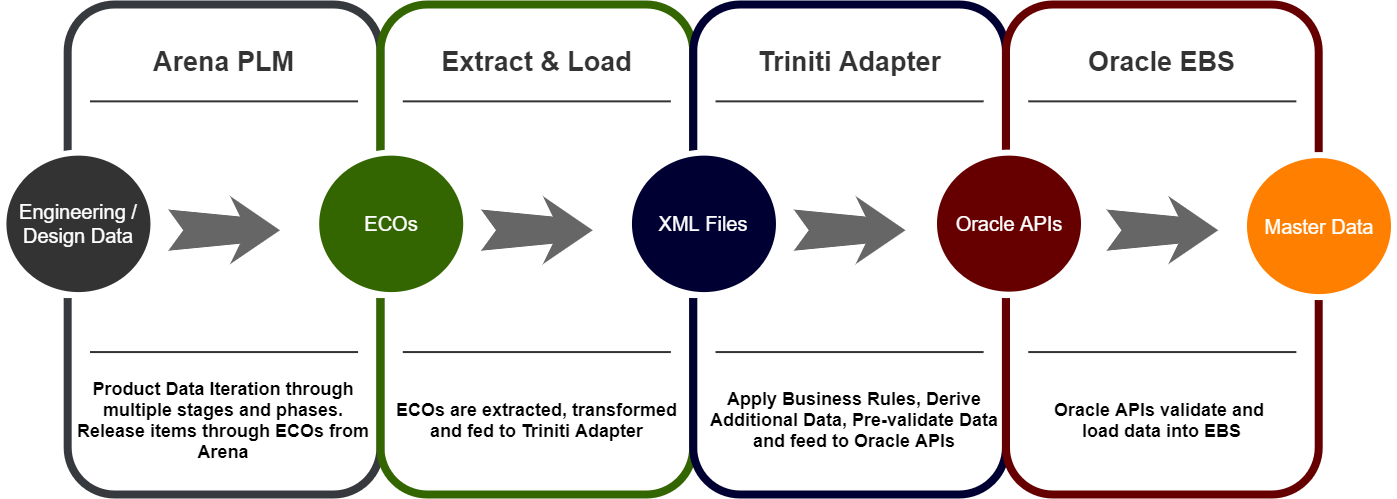

Data Flow from PLM to ERP