Triniti Develops IIoT Production Monitoring Solution for F&B Customer

Customer Industry Vertical

-

Food and Beverage (F&B)

About the Customer

-

The customer is one of the foremost private sector companies, with businesses spanning FMCG (fast-moving consumer goods), paperboards, packaging, agribusiness, and information technology.

Project Outcomes

-

Integrated production process leveraging existing machines (Weighing, Packaging) and HMIs (Human Machine Interfaces)

-

Realtime detailed Production Monitoring facilitating quick response to outliers

-

Equipment Monitoring with event notifications and trend analysis

-

Compliance and Control taking into account EGA (Extra Grammage) variation for the F&B industry

Solution Highlights

-

Built custom connection to older Ishida machines (proprietary data stream)

-

Handled High Volume stream - 1650 parameters per second across 30 devices

-

Architected solution per client’s policy of housing all data on internal servers

-

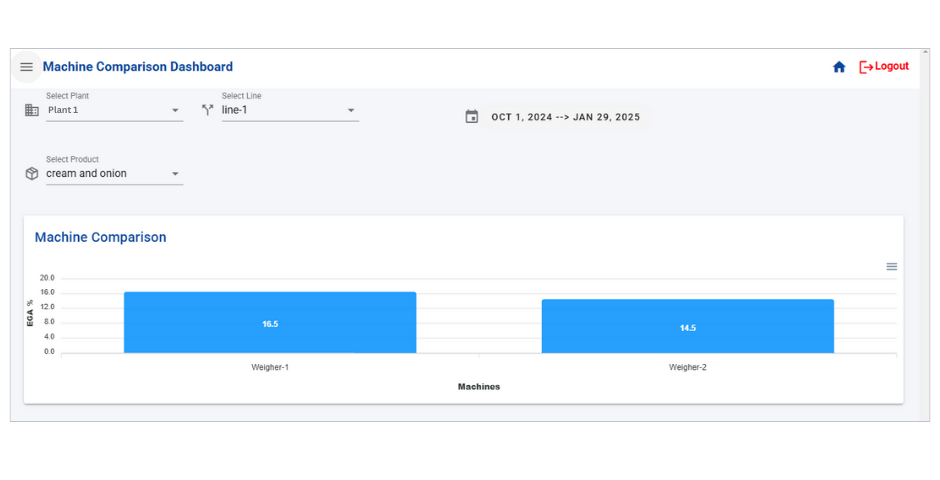

Developed Reports and Dashboards - Machine, line and SKU-wise EGA; Performance comparison for different flavours, weighers and lines

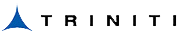

Line-wise EGA & OEE Analysis

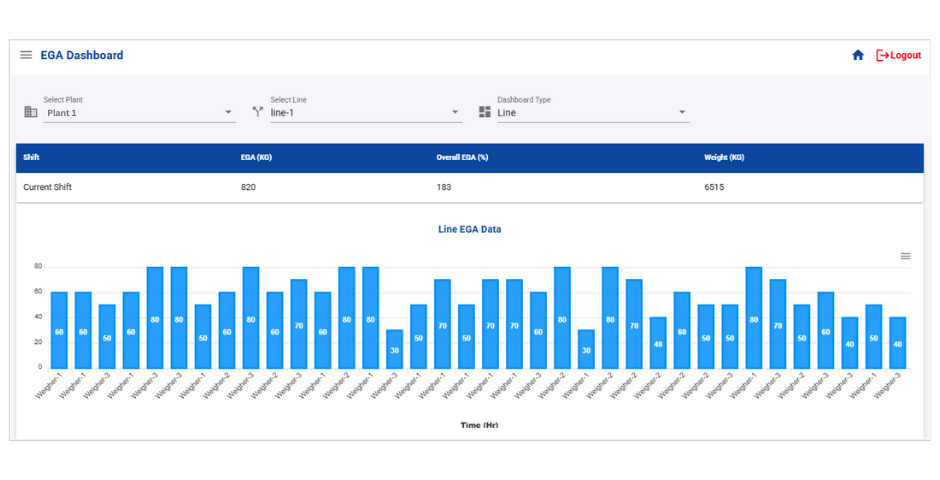

Machine Performance Comparison Dashboard (EGA)

Line-wise and Machine wise Comparison (EGA)

Line-wise EGA and OEE Analysis

Detailed case study to followClick here to read more success stories